Contact

Contact

Looking for the right Product

or having questions?

Request sample

PVA Product finder

Be the first to know what’s new in Kuraray’s polyvinyl alcohol product portfolio!

Subscribe now Contact

Contact

Looking for the right Product

or having questions?

KURARAY POVAL™ Applications Packaging Protective Packaging

KURARAY POVAL™

Kuraray offers various solutions to the packaging industry, paving the way for sustainable packaging materials through the utilization of KURARAY POVAL™ (Kuraray’s polyvinyl alcohol). One such solution supports the transition from traditional foamed cushioning materials for shipping goods, like expanded polystyrene (EPS), to biodegradable options. This shift helps reduce plastic waste.

As environmental awareness has grown in recent years, the packaging industry has steadily shifted toward more sustainable materials. Protective packaging materials made with the support of KURARAY POVAL™ are seen as a solution for sustainable cushioning materials and other solutions.

KURARAY POVAL™ is known as one of the few resins that is inherently biodegradable in aqueous solution, making it suitable as an ingredient in compostable materials, which is also supported by BPI certification across a broad range of grades.

Our selected grades of KURARAY POVAL™ have received BPI certification in North America. BPI certification of KURARAY POVAL™ resin as an ingredient indicates the end-of-life opportunity for a compostable product. This means our KURARAY POVAL™ resin has undergone a rigorous process, including third-party verification, and has been found to comply with scientific standards. These standards ensure that KURARAY POVAL™ resin will break down as expected in commercial facilities operating in accordance with ASTM D6400 and will not negatively impact compost quality.

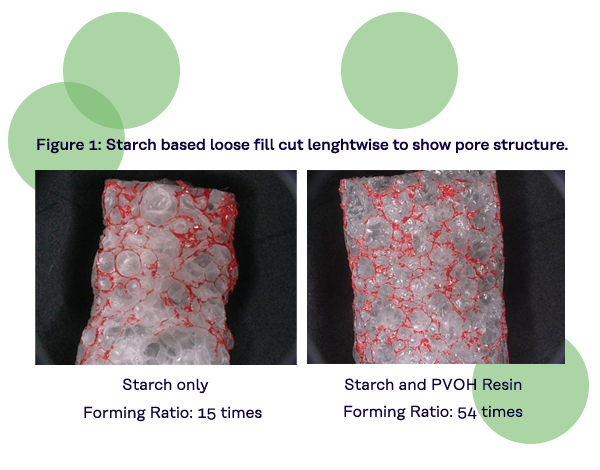

Although it is challenging to create a usable foam using only biodegradable starch, adding 30 % KURARAY POVAL™ results in a more stable and effective foamed material. This process yields a foam with excellent cushioning properties, ensuring the safety of products during shipping. The addition of KURARAY POVAL™ leads to a much more regular foam structure and a significantly enhanced foaming ratio compared to pure starch, as shown in Figure 1. Moreover, adding KURARAY POVAL™ enhances production efficiency and the overall quality of the foam, allowing for the production of reliable packaging materials.

Cushioning material made with the addition of KURARAY POVAL™ is remarkably lightweight, weighing only 25% as much as for starch-based foam, yet it provides exceptional strength and durability. This unique combination of lightness and strength reduces shipping costs while ensuring excellent product protection. Its lightweight nature also makes it easy to handle, improving work efficiency. Furthermore, its durable structure ensures long-lasting performance.

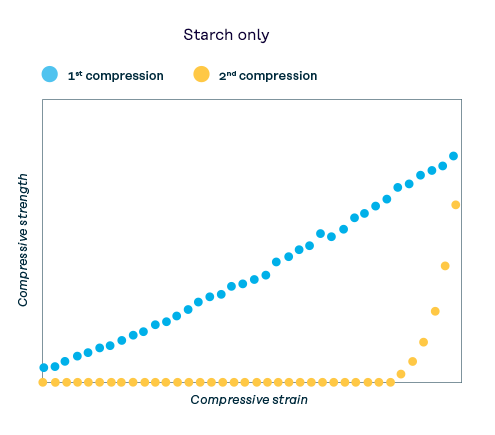

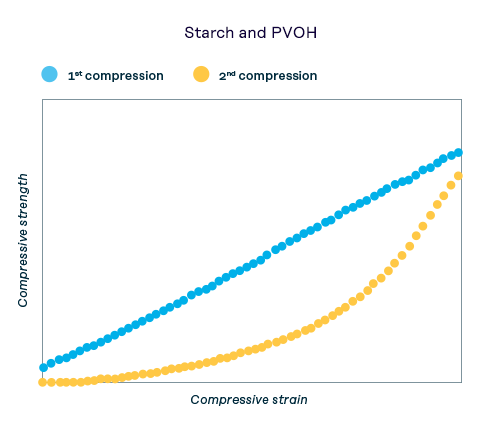

Adding 30% KURARAY POVAL™ to a starch-based foam recipe significantly increases the foam's flexibility and resilience, making it twice as resilient as foam made solely from starch (Figure 2). This enhanced flexibility allows the material to absorb and cushion repeated impacts, providing superior protection for the packaged product. The material's high resilience also safeguards the product against vibrations and impacts during shipping, significantly reducing the risk of damage.

| Sample | Density | Resilience* |

| - | kg/m³ | % |

| Starch only | 91 | 6 |

| Starch + PVOH | 17 | 52 |

*Based on compression energy ([Compression energy @ 2nd compression]/

[Compression energy @ 1st compression])

Measured under absolute dry condition

Figure 2: Resilience of the foam against distortion graphs of starch based cushioning materials.

Starch-based cushioning materials containing KURARAY POVAL™ exhibit excellent insulating capability, comparable to those of polystyrene. This effectively protects products from temperature fluctuations, making them ideal for transporting temperature-sensitive goods. A high level of insulation is crucial for maintaining product quality by minimizing the effects of external temperature changes. Packaging materials with superior insulating capabilities are particularly effective for transporting products requiring strict temperature control, such as food and medicine.

Measurement method: heat flow meter(JIS A 1412-2)

Measurement temperature: 25℃

| Characteristic of the object | Unit | Starch / PVOH foaming body | Foamed polystyrene |

| Bulk Density | kg/m³ | 11 | 9.7 |

| Thermal Conductivity | W/(m.K) | 0.04 | 0.04 |

The unique properties of KURARAY POVAL™ in starch-based cushioning materials – including its strength, flexibility, and static reduction – make it ideal for safeguarding various items. It is most suitable for protecting fragile items like electronics, glassware and precision equipment, ensuring they reach their destination safely.

In accordance with Commission Regulation [EU] 2023/2055 [Restriction of microplastics intentionally added to products] partially hydrolyzed KURARAY POVAL™ grades most commonly used for manufacturing of starch-based cushioning materials are exempt from being classified as synthetic polymer microparticles. Water solubility tests conducted according to the OECD 120 test method [as specified in EU 2023/2055 Appendix 16] confirmed that these KURARAY POVAL™ grades fulfill the solubility criteria of > 2 g/L, qualifying them for this exemption.

Kuraray is committed to developing sustainable materials in

compliance with international environmental regulations

to help build a more conscious society.

We will also contribute to achieving this goal

through our carefully selected product portfolio of KURARAY POVAL™.

Do you have any questions, need technical support or would like to request a sample?