Contact

Contact

Looking for the right Product

or having questions?

Request sample

PVA Product finder

Be the first to know what’s new in Kuraray’s polyvinyl alcohol product portfolio!

Subscribe now Contact

Contact

Looking for the right Product

or having questions?

KURARAY POVAL™ Applications Textiles

KURARAY POVAL™

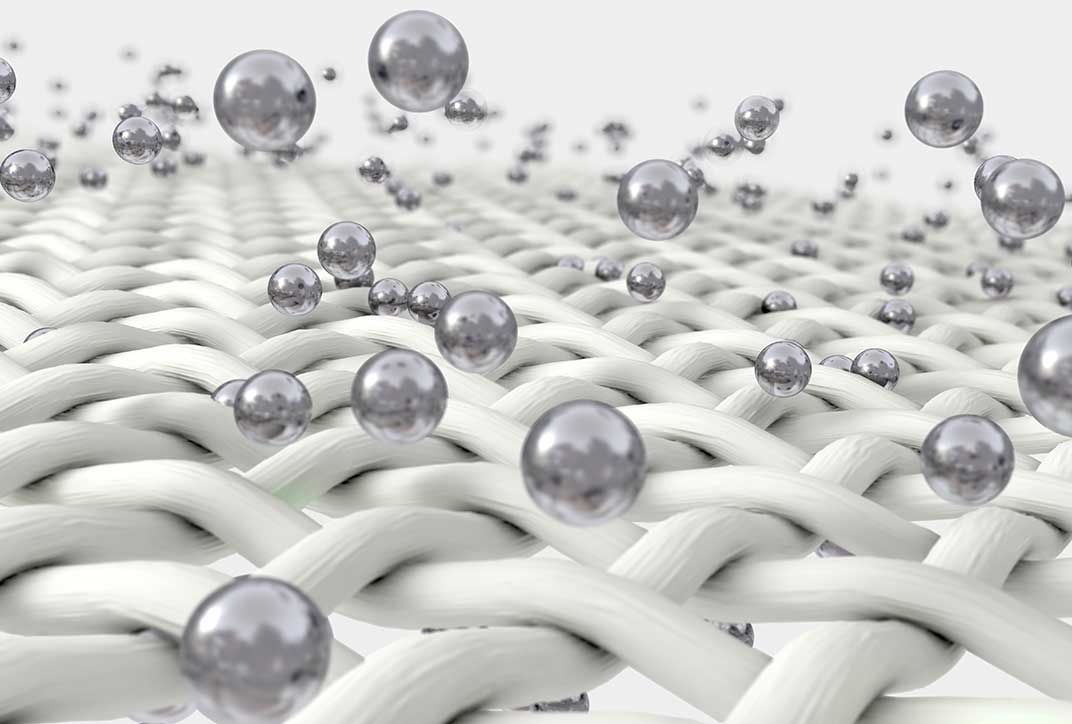

KURARAY POVAL™ and ELVANOL™ polyvinyl alcohol (PVOH) are the superior products for textile warp sizing in spun and filament yarn. Providing a protective coating for spun and filament yarn, KURARAY POVAL™ and ELVANOL™ allow yarn to be desized in hot water and are more effective than starch. The excellent film-forming capabilities provide protective coatings for spun and filament yarn, yet are still tough enough in abrasion resistance. Our innovative and dedicated team is committed to providing the highest quality of products and services with less environmental impact for our customers in textile industries around the world.

We conduct sizing trials, provide yarn analytical reports, and more. Our advanced technology and decades of experience allow us to collaborate with customers to produce breakthrough and inventive textile products. Our products improve productivity and ensure our customers stay ahead of the competition.

16 grades of KURARAY POVAL™ and ELVANOL™ have been approved as textile auxiliaries for use in the processing of GOTS-certified textile products. For more details, please click here.

As we are a green company, our products are designed to minimize environmental impact with our special PVOH recovery system to reduce environmental wastage efficiently.

We provide accommodating and customized technical service globally for the convenient access of the customers in every corner of the world.

In order to reduce warp breakages and weft-stops, KURARAY POVAL™ and ELVANOL™ PVOH are used to improve toughness and smoothness and elasticity of yarns, binding fluffs for good shedding, particularly on spun polyester blended yarns. KURARAY POVAL™ and ELVANOL™ PVOH are superior to other materials, like starch, because they are stronger and provide the required protection. The excellent weave performance of KURARAY POVAL™ and ELVANOL™ PVOH allows for advantageous and difficult-to-weave constructions. When KURARAY POVAL™ and ELVANOL™ PVOH are used instead of starch, shedding on the slasher decreases due to the efficiency of polyvinyl alcohol. This minimizes waste in the weave loom.

The film-forming characteristics of KURARAY POVAL™ and ELVANOL™ PVOH make them ideal for yarn sizing. Their adhesion, toughness, and film strength are reflected in improved physical properties of the sized yarn. Along with superior characteristics, less KURARAY POVAL™ and ELVANOL™ PVOH are needed when compared to starch. The improved toughness and smoothness of yarn, when sized with KURARAY POVAL™ and ELVANOL™, is indicative of good abrasion resistance against reed motion, shedding motion, and high tension on the weave loom.

The unique molecular structure of the ELVANOL™ T-grade copolymers is extremely chemically stable, and is not hydrolyzed or otherwise chemically altered in the heat and stresses of a size recovery system. ELVANOL™ T-grades are not adversely affecting in the desizing process and can be reused, even when washed with sodium hydroxide. KURARAY POVAL™ and Elvanol™ copolymers are degradable in properly designed and operated activated sludge waste water treatment systems. When a size recovery system is installed at the desizing stage, virtually all ELVANOL™ is eliminated from the waste water. ELVANOL™ T-grades are easily recovered and reused in any type of commercially available ultrafiltration system. Reuse is straightforward, as there is no viscosity change during desizing, ultrafiltration, or storage. High concentrations can be achieved, reducing transportation costs and providing maximum flexibility in reuse of the reclaimed solutions.

Do you have any questions, need technical support or would like to request a sample?